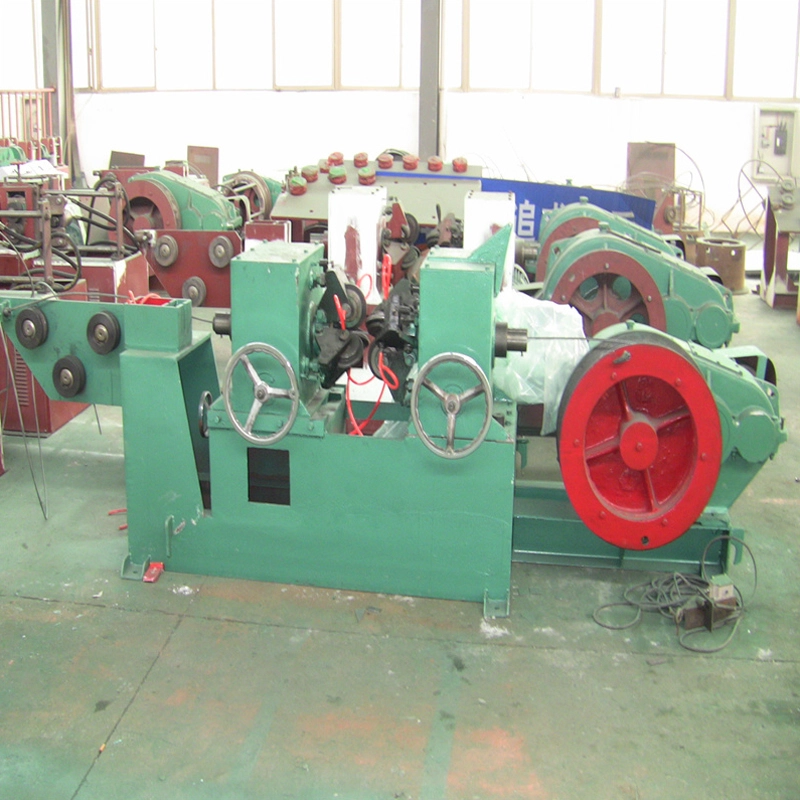

The Cold-rolling Ribbed Bar Production Line is a specialized machinery used to transform common low-carbon steel or low-alloyed steel into bars with three faces of crescent rib. This process involves several stages of cold rolling and rib extruding, resulting in a bar with enhanced strength and improved extensibility.

Enhanced strength: The ribbed bar produced by the Cold-rolling Ribbed Bar Production Line exhibits higher intensity compared to cold-drawn steel thread. The cold-rolling process enhances the strength of the bar, making it capable of withstanding heavy loads and providing structural stability. This is particularly important in infrastructure projects where durability and safety are paramount.

Improved extensibility: The ribbed bar produced by the Cold-rolling Ribbed Bar Production Line also offers better flexibility compared to cold-drawn steel thread. The cold rolling and rib extruding processes enhance the flexibility of the bar, allowing for easier bending and shaping. This makes it more adaptable to different construction requirements, enabling architects and engineers to create complex and innovative designs.

Versatility: The Cold-rolling Ribbed Bar Production Line can produce ribbed bars of different sizes and shapes, enabling architects and engineers to create complex and innovative designs. This makes it an ideal choice for a wide range of construction applications, including highways, airports, and various architectural projects.

Excellent bonding properties: The ribbed bar produced by the Cold-rolling Ribbed Bar Production Line offers excellent bonding properties with concrete. The ribs on the surface of the bar create a mechanical interlock with the surrounding concrete, enhancing the overall structural integrity. This ensures a strong and reliable connection between the bar and the concrete, making it suitable for reinforced concrete structures such as beams, columns, and slabs.

High efficiency and productivity: The Cold-rolling Ribbed Bar Production Line offers high efficiency and productivity. The automated processes ensure consistent quality and precise dimensions, reducing waste and optimizing material usage. This not only saves costs but also improves the overall construction timeline.

The Cold-rolling Ribbed Bar Production Line is a versatile and efficient machinery that produces ribbed bars with enhanced strength, improved flexibility, and excellent bonding properties. Its consistent quality, precise dimensions, and versatility make it an essential tool for the construction industry, enabling the creation of safe, durable, and innovative structures.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China

Why Choose CANDID? Professional Service & Reliable Quality You Can Trust

How Barbed Wire Making Machines Shape Different Twisting Styles for Enhanced Security

![[Turning Crisis into Opportunity] – CANDID Helps Client Overcome Technical Challenges, Boosting Production Capacity! [Turning Crisis into Opportunity] – CANDID Helps Client Overcome Technical Challenges, Boosting Production Capacity!](/uploads/image/20250331/gabion_mesh_machine3.webp)

[Turning Crisis into Opportunity] – CANDID Helps Client Overcome Technical Challenges, Boosting Production Capacity!