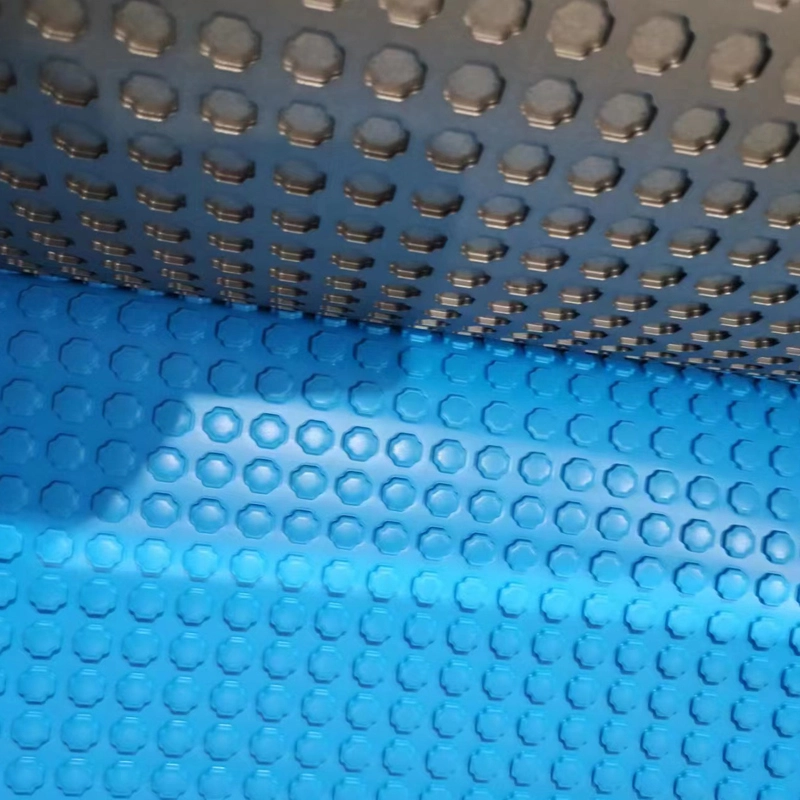

Decoupling/dimpled pad is a special material mainly used for tile laying, especially in indoor and outdoor waterproofing applications. Decoupling pad/dimpled pad has a three-layer structure, good breath-ability, and can adapt to various base conditions, including moisture, vibration, a certain degree of unevenness or cracking, settlement, freeze-thaw, etc. The main function of decoupling pad/dimpled pad is to protect ceramic tiles from damage, so they are often used in large board tiling. In addition, it can achieve synchronous construction of tile laying and waterproofing, greatly improving construction efficiency. The core function of decoupling pads is to prevent the force of structural cracking from being directly transmitted to the bricks, but it is required that the original structure at the bottom must meet the standard for flatness.

CANDID decoupling pad/dimpled pad production line can customized the pad according to client's requirements, such as the decoupling pad's width, the shape and suitable for different raw material.

No. | Item | Parameter |

1 | Working width | 1000-2000mm |

2 | Thickness (mm) | 3 (Permissible: ±2 %) |

3 | Mechanical speed | 3-10m/min |

4 | Total extrusion capacity | 600-800kg/h |

5 | Forming roller diameter | Φ600 |

6 | Forming roller length | 1400-2400mm |

7 | Winding roller diameter | Φ800 |

8 | Non-woven fabric unwinding diameter | Φ1200 |

9 | Screw speed | 0-70 rpm |

10 | Nitrification depth of screw | 0.4-0.7mm |

10 | Nitrogen hardness of screw | HV720-940 |

1. We have our own machining lathe, and all spare parts ensure 100% accuracy, making the equipment run more stably.

2. Adopting a hanger style cavity, the plate is evenly and smoothly released, with flexible and convenient adjustment.

3. Our mold using alloy tool steel, the inner surface is polished and polished, plated with hard chromium, and has a longer service life.

Get expert advice, learn more about our products, meet your needs, and boost production efficiency!

RM.1405, NO.346 Qingtai Street, Hangzhou, China

Why Choose CANDID? Professional Service & Reliable Quality You Can Trust

How Barbed Wire Making Machines Shape Different Twisting Styles for Enhanced Security

![[Turning Crisis into Opportunity] – CANDID Helps Client Overcome Technical Challenges, Boosting Production Capacity! [Turning Crisis into Opportunity] – CANDID Helps Client Overcome Technical Challenges, Boosting Production Capacity!](/uploads/image/20250331/gabion_mesh_machine3.webp)

[Turning Crisis into Opportunity] – CANDID Helps Client Overcome Technical Challenges, Boosting Production Capacity!